Equipment for industrial capacitor testing

Since its founding in 1956, Kohan Electronics (Japan) has been the leading specialized manufacturer of industrial testing equipment for capacitor products. The company Kohan develops and sells a line of automated test systems for the entire range of capacitor products manufactured by leading global manufacturers.

The main types of capacitors tested:

- Aluminum Electrolytic

- Tantalum Electrolytic

- Tantalum chip capacitors

- Ceramic multilayer

- Film Multilayer

- Super-capacitors

Features of the company’s products:

The company’s products are always individually designed automated lines with varying degrees of automation:

- from the formation of leads,

- visual quality control,

- testing electrical parameters,

- up to packing batches of capacitor products.

The degree of automation is determined at the design stage based on the required performance and economic feasibility.

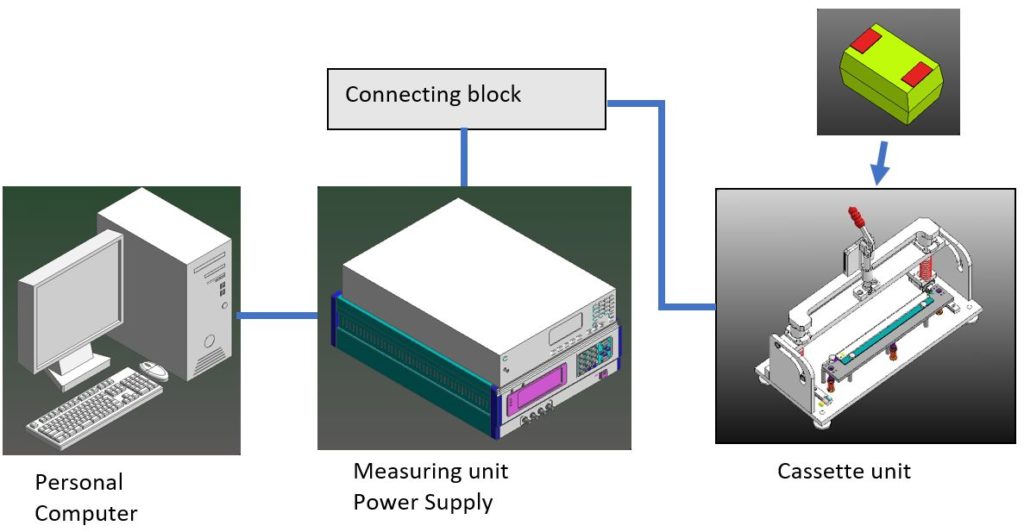

Model VCB-D001. Phase difference Type Capacitance Bridge

Size: W350・H120・D480 (mm)

1.Fundamental Measurement Principle

The phase difference is digitally measured with a bridge composition which is set as 1 to 1 ratio between a standard resistor (Rs) and a measured capacitor (Zx).

2.High-Speed Measurement

A nominal capacitance and a dissipation factor values are measured simultaneously and repeatedly with 120 Hz and 1 kHz frequencies. The measuring speed for 120 Hz is 16 msec. and for 1kHz is 10 msec., high-speed measurements are actualized.

3.High-Accuracy Measurement

With the basis of an accuracy of an oscillator and a temperature coefficient of a standard resistor, stable measurement values are maintained for long time with onetime calibration. Also, a contact resistance is separated on the vector, and a stray capacitance is corrected which makes a high-accuracy measurement possible.

4.Repetitive Measurement

The measured values are derived by averaging those measurements of maximum repetitions, for 120 Hz is 9 times (9 cycles) and for 1 kHz is 41 times (41 cycles).

5.Rapid Discharge

In order to avoid the influence of the residual voltage of a measured capacitor, rapid discharge function, which is used before the measurements, is installed.

6.Residual Voltage

Because of using a phase difference measuring method, those high-speed measurements are not influenced up to 5 V of a residual direct current voltage.

7.Direct current Voltage Overlay

A rapid charging function of a direct current overlay voltage(0-5 V DC).

Internal Fix: 0 V or 1.5 V DC

External power supply connecting: 0-5 V DC

8.ALC. Function

The measuring voltage, which is applied to a large capacitance and a high dielectric constant capacitor, instantaneous auto-adjusting function is installed

Examples of installations manufactured and delivered

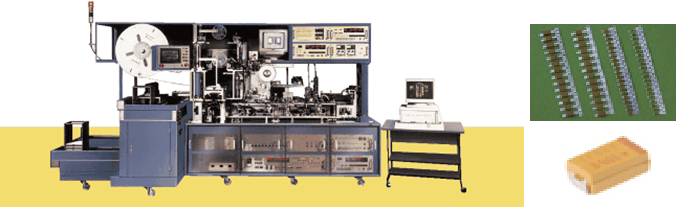

Model FMT-1001. Tantalum Capacitor Total Automatic Inspection System

Inspection subject: OP/SH/Z or ESR/LC1/LC2/C/tanδ

The complex of equipment includes:

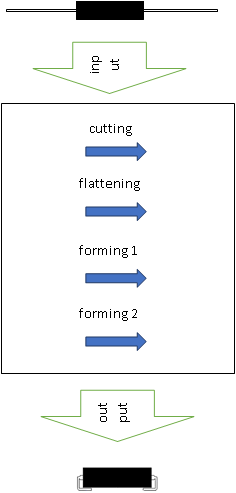

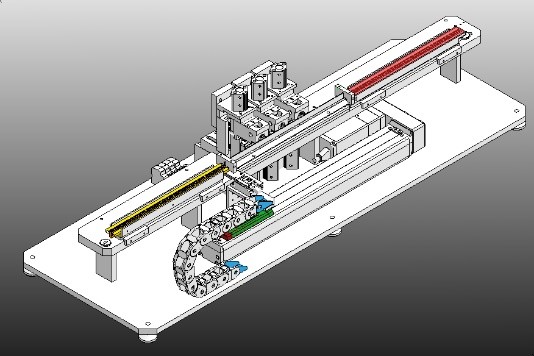

FMS-1001, Chip Capacitor Lead Frame Forming Machine.

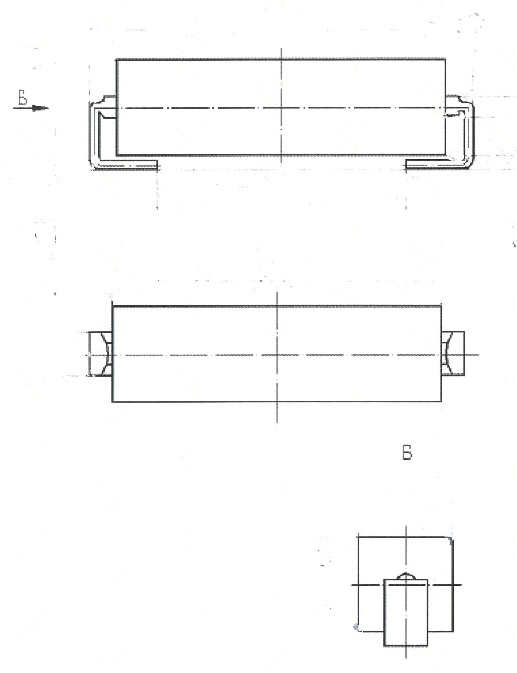

The capacitor leads are made of ferro-nickel tape and are molded in a special way to enable automated surface mounting of the capacitors on the printed circuit board. Tantalum chip capacitors come to the pin forming section with direct leads of oversized dimensions (A). On the FMS-1001 unit, the pins are trimmed to the size specified by the technical conditions, and then the pins are folded to give the product a specified look (B).

Reed Switch Leads Forming Facility

FMS-1001 can be modified to Reed switch leads forming machine. Reed switch — a hermetically sealed magnetically operated contact – is an item which construction consists of two contact-blades soldered into the glass tube which is additionally housed by a plastic covering case. Reed switch leads forming — a set of process operations resulting in the reed switch leads geometry specified in the drawing.

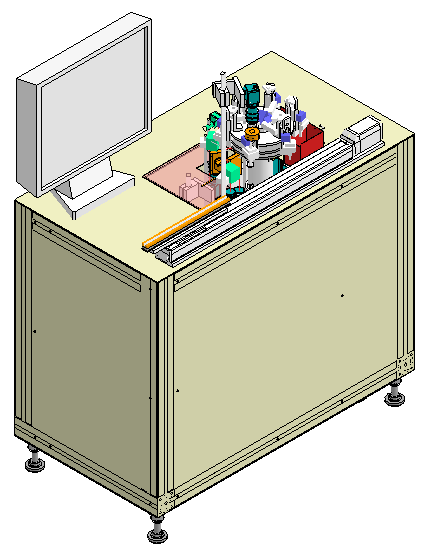

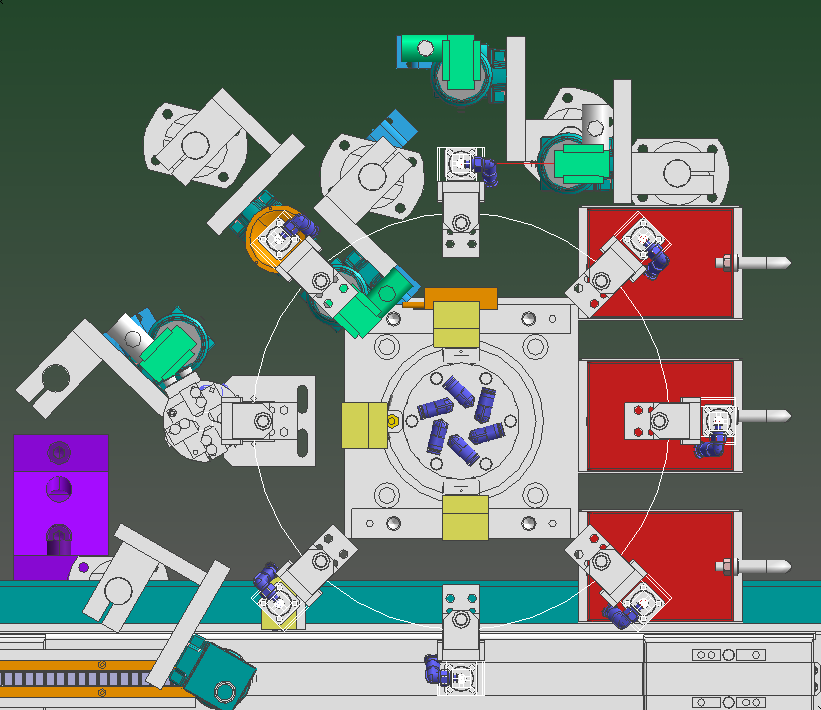

–KMS-1001, Tantalum Capacitor Total Automatic Inspection System

– MVS-1001, Visual Testing Machine

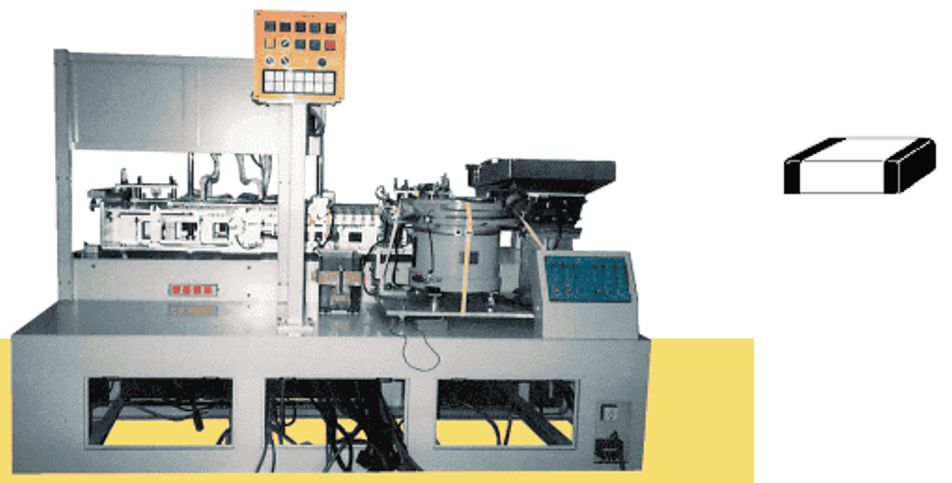

Model TC-6202 Tantalum Capacitor Molding Chip Inspection Equipment

Inspection subject: OP/SH/Z or ESR/LC1/LC2/LOGC/tanδ

Model TC-7101. Molding Chip A-Type Final Product Inspection Equipment

Inspection subject: SH/C/ tanδ/LC1/LC2/

Model DT-7002 Dip type Tantalum Capacitor full Automatic Inspection Equipment

Inspection subject: LOGC/ tanδ/Z or ECR/

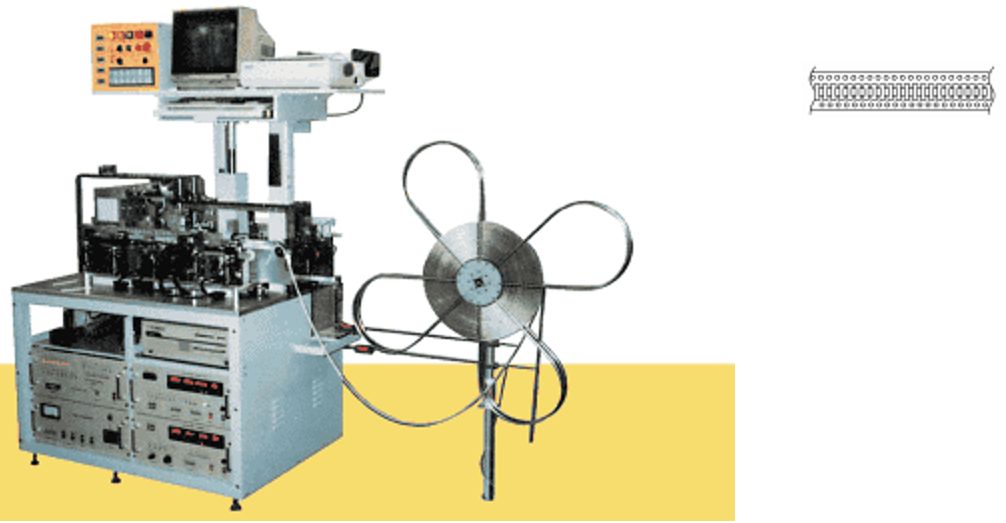

Model FCF-1001 Hoop type Film chip capacitor Automatic Inspection Equipment

Inspection subject: 10K/D1(CO)/TV/IR/ 10K/D2/1KC/δ

Model MX-1001 Matrix-type Product Handling Inspection Equipment

Inspection subject: Z or ESR/LC/C/tanδ

Model TTS-2000. Re-Inspection Standard Sorting and Taping System

Re-Inspect the characteristically inspection equipment with the taping process ability.

Model FC-4001. Multilayer Film Chip Capacitor Final Product Inspection Machine

Inspection subject: 10K/D1(CO)/TV/IR 10K/D2/1K・S/δ

Model MM-5001. High-Voltage MF Capacitor Line Connecting Inspection Equipment

Inspection subject: AC ・TV/IR/10K/D2/1K・C/ tanδ/

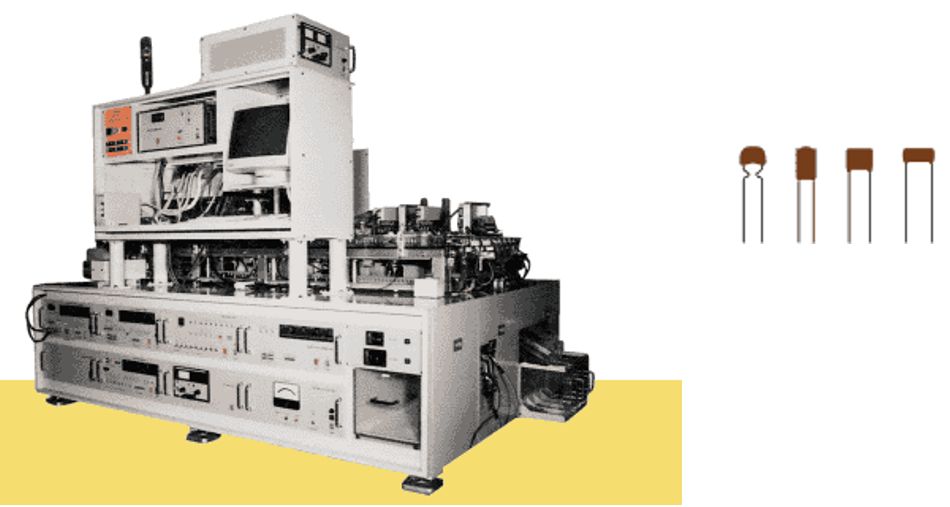

Model VT-1001 Varistor Three Side Electrodes Inspection Equipment

Model DF-804S CPU Equipped MF Capacitor Automatic Inspection Equipment

Inspection subject: CO/MT/CLEARING/ DC ・TV/ AC ・TV/ IR/10K/D/1K・C/D

Model DE-405. Aluminum Electrolytic Capacitor Automatic Inspection Equipment

Inspection subject: MT/SH/LC (160V)/C/D (5000 μ F)