POWDER FORMING MACHINE FOR POWER INDUCTOR

This press machine is designed to press form supplied frame coil into a determined shape with a coated metal powder. The forming dies have a separate structure. The main pressure is applied vertically by individual AC servomotors from top and bottom with separately supplied powder for each upper and lower die. Press force is also applied up to approximately 5 tons.

By using different AC servomotor for each of upper and lower press die, the position setting can be done on the control panel, so that the adjustment and maintenance are no longer troublesome.

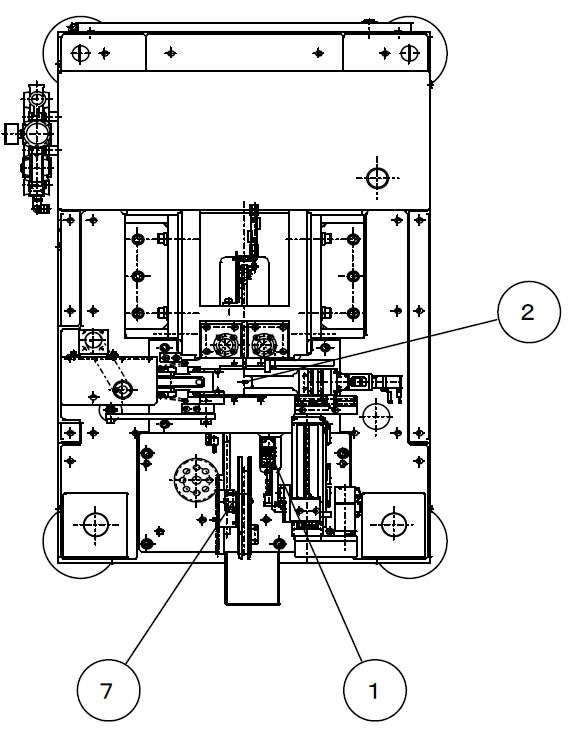

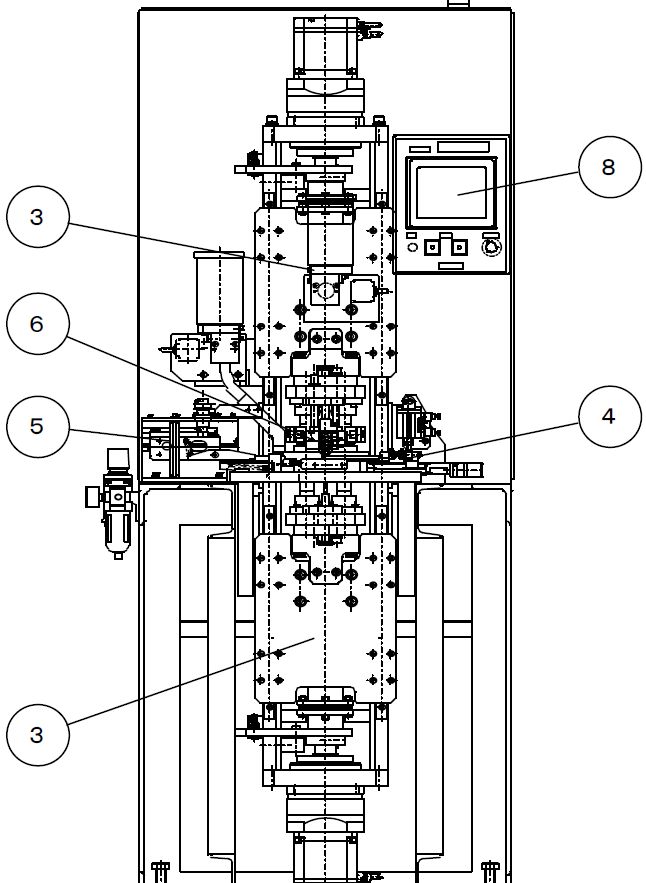

①Coil Supply Section: Coils are manually set and fed into a die.

②Die set: This section consists Upper Die, Upper Supply Die, Middle Die, Main Unit, and Lower Die.

③Die Set Drive Section (Vertical): Tis consists Bowl Screws and AC Servomotor, etc. The well-balanced pressure is applied by separate vertical drives. The final press position can be set on the operation touch panel. The setting range of the upper die is up to 1.1 mm above from the top frame surface, the setting range of the lower die is up to 4.35 mm below from the frame top surface.

④Die Set Drive Section: The middle die and upper supply die shift.

⑤Powder Supply 1: The powder is supplied into the upper supply die by the shuttle.

⑥Powder Supply 2: The powder is supplied into the main unit by the shuttle.

⑦Ejection Section: This section ejects the formed pellets.

⑧Controller: This programmable controller mainly controls the motor positioning, the torque control, etc. For data input or switches, the touch panel is used.

Machine Specifications:

| Pellet Dimensions | 10 mm (Standard) |

| Powder | To be determined with customer |

| Maximum Pressure | 5 ton |

| Machine Dimensions | 700 (W)х1000(D)x1975(H) mm |

| Electricity Main Unit | AC 200 V, 3 phases, 5,5 KWA |

| Air Pressure | 0,5 MPa or more, 50 Nl/min |